PROTOTYPE IN ACETATE

WORK FLOW

CUTTINGCNC ROUTER

Using three dimensional imaging, we then cut out the internal and external forms of the frames with our CNC routing machines.

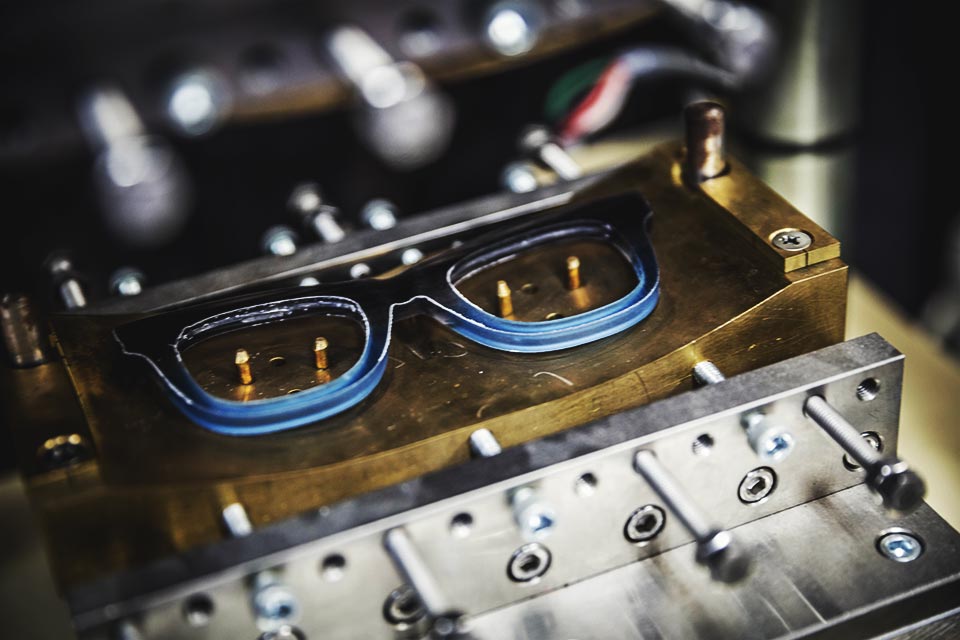

CURVINGforming the curve

After routing, a frame is set in a metal mold and heated, whereby a curve is applied through a pressing technique, corresponding to each curve in the mold.

SANDINGthe filing process

After the exact curves of the frames have been established, our craftsmen apply shape, both roundness and edging, methods which are akin to the frame’s handcrafted detail.

BUFFINGhand polishing

Again adding to the handmade aspects of our manufacturing process, after sanding we will then use three-stage polishing machines, buffing the frames from matte to high gloss, depending on the client’s preferences.

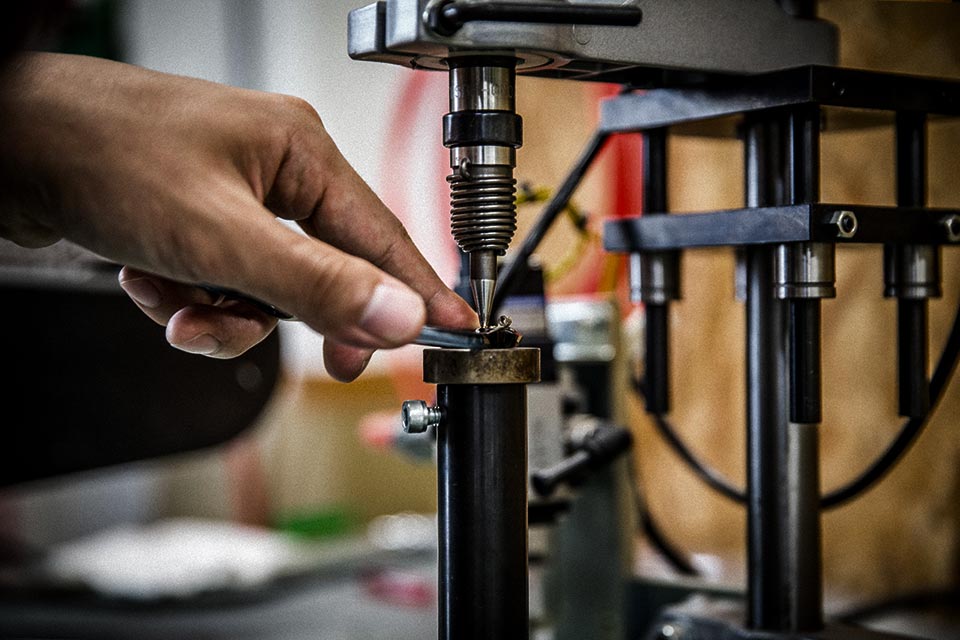

ASSEMBLY

Finally, each piece is carefully assembled, adjusting the fittings and frames to each client’s respective specifications.